PS Foam Sheet Extrusion line

1. Product Introduction:

This production line adopts double-screw foam sheet extrusion technology. PSP foam sheet is a kind of new-type packing material with the features of heat preservation, safety, sanitation and good plasticity. It’s mainly used to make various types of food containers,such as lunch box, dinner trays, bowls etc by thermal forming. It’s also can be used to make advertisement board, industrial products packing and so on. It has performance, big capacity, high automation and yields quality products.

2.Main Technical Parameters:

SPECIFICATION FOR PS FOAM SHEET EXTRUSION LINE | ||||||||||

Model | Unit | SJ-PSP75/90 | SJ-PSP105/120 | SJ-PSP110/130 | SJ-PSP135/150 | |||||

Screw diameter | mm | Ø75/90 | Ø105/120 | Ø110/130 | Ø135/150 | |||||

Foam ratio | 10-20 | |||||||||

Width of product | mm | 640-1040 | 640-1200 | 640-1200 | 640-1200 | |||||

Cutting method | single cutter | single cutter/Double cutter | ||||||||

Thickness of product | mm | 1.0-3.0 | 1.0-4.0 | 1.0-4.0 | 2.0-5.0 | |||||

Cooling method | cooled by wind and water | |||||||||

Capacity(approx) | Kg/h | 50-90 | 160-240 | 200-280 | 280-360 | |||||

Total power(approx) | kw | 140 | 200 | 220 | 260 | |||||

Overall size(L*W*H) | m | 22*4.0*2.8 | 25*4.1*2.8 | 26*4.2*3 | 28*4.2*3.2 | |||||

Total weight(approx) | T | 10 | 13 | 14 | 16 | |||||

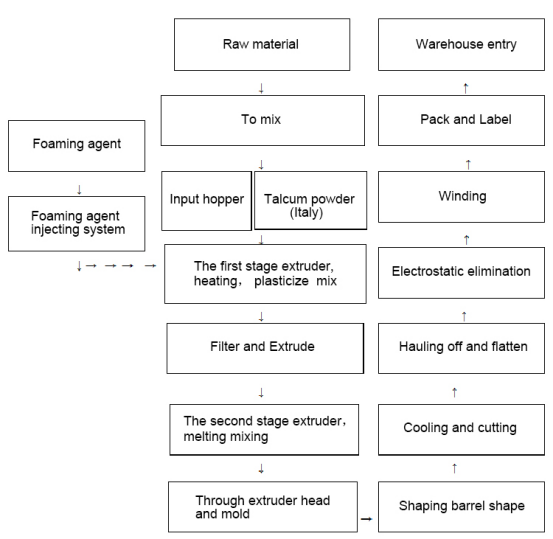

Process flow: